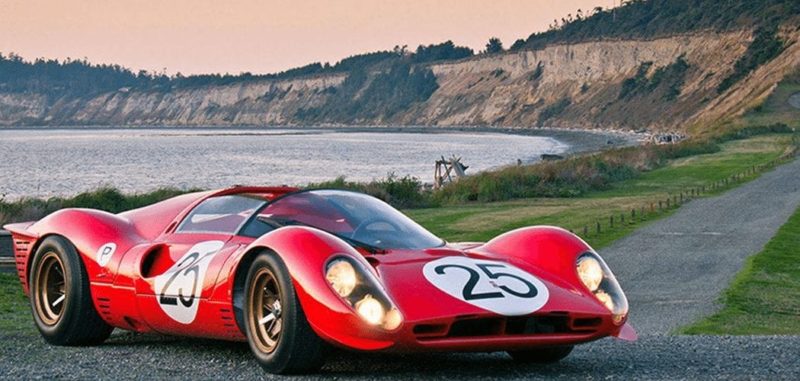

After a short hiatus, I returned this week to the P4 by Norwood lab to catch up with my good friend Tim Taylor, check up on the progress of the latest P4 by Norwood and discuss the most electrifying season of Formula 1 in years.

(Part 1, Part 2, Part 3, Part 4)

No surprise, Tim had a slew of his team’s latest creations to share, and for the uber-car enthusiast (i.e. borderline fanatic) these are the bits I, and by “I,” I mean “they,” of course, enjoy the most.

For hand-built, one unit at a time builds, there is a no mail-order catalog from which to source those small parts. Yet those small parts make-up the intricate details that put cars, such as the P4 by Norwood, into the true, world-class performer category. They’re not just another pretty Ferrari made for a trip to the next car show.

Those intricate details include dual gas tanks, each with its own fuel surge tank, and Bosch high pressure fuel pump, standard equipment on Porsche 911 turbos and capable of 300 liters/hr at 45psi. Each tank also contains its own lift pump to pull fuel from the main fuel tank into the surge tanks to prevent any chance of slosh or air in the lines. A dry sump oil tank and vintage-look tartop battery case round out the list of custom hand-fabricated components. A fitting tribute to the racing heritage of the era; if you need it, build it. Unlike the fabrication team of the late 60’s, Tim’s parts are designed to last for years, not just for 24hrs at Daytona.

The artful display of metal forming under the hood does not stop at the oiling and fuel system. Custom fabricated headers, courtesy of ICEngineworks, look nothing short of spectacular as their elegant bends extend from the block to the collectors just behind the engine. Custom, hand-fabricated headers for a 575 Maranello engine – if you have followed this far, it should go with out saying that there are 2 things Tim will never be accused of not being – a perfectionist and a visionary.

For this unit an upgraded wiring schematic was also created. The new diagram, designed by an automotive electro-engineer, is scale to the car and contains all the measurements for each individual wire.

With the wiring, fuel and oil delivery systems in place, the team at P4 by Norwood will now turn their attention to plumbing for engine and brake cooling and finishing off the exhaust routing to the rear of car. These are the final steps before the freshly painted body panels go back onto the car, and we finally see what nearly a year’s worth of dedication and perseverance looks like.